![]()

Gas Scooter Troubleshooting

Learning how to gas scooter troubleshoot can save you money We show you how, and where to go for gas scooter tools

Trouble Shooting Reference for Gas Powered Scooters

This page is provided to help you find and repair problems associated with gasscooters and is not intended to replace your repair manual. To successfully use this guide you will be taught how to identify the major problem with your scooter, and then use the guide to make the diagnosis and repair. I have listed the most likely causes first to help you quickly get your gas scooter back on the road. You may find it beneficial to read an excellent article on gas scooter clutches and transmissions first. If you are looking to resolve an engine problem try Troubleshooting gas scooter Engine Problems.

DISCLAIMER: Maintenance, disassembly and repair of your gas powered scooter should only be performed by people with sufficient mechanical skill or experience so that no unsafe repair or modifications are made.

Drive Train Problems

Gas Scooter Moves When Engine Is Idling:

This problem can be a safety issue as well as a maintenance challenge and should be addressed very quickly.

-

Typically idle creeping is caused by an engine idle setting that is set too high. Reasons typically include a kinked throttle cable (gently straighten the kink) or a binding throttle cable (try to work some WD-40 in the cable sleeve). You need to also check that the throttle linkage at the engine is not binding. With the engine off, gently try the linkage with your fingers while holding the twist grip in full throttle position. Engines also have an idle screw, but if you have not messed with the setting, this wouldn't change. Observe if the throttle linkage is resting on the idle stop though. You can try spraying the cold scooter with a carburetor cleaner and let it soak a few hours if it's binding.

-

It's possible the drive chain is too tight and is putting enough side load on the clutch to cause it to partially engage. Make sure your chain is well lubricated and is not too tight or binding anywhere. I have seen this happen where a piece of new chain was put into repair an old chain. At certain positions the chain would be tight, and at others loose.

-

If your gas scooter takes off by itself when the engine is started, that is an indication that the clutch is badly in need of lubrication. It's very possible that your centrifugal clutch is overheated or not oiled properly. See a full discussion below under the heading Erratic Engagement of Clutch. Turn the engine off and park the machine up against a tree or fence to prevent it from taking off when you crank the engine again. You can also put the rear end up on centerblocks so the rear wheel is not touching the ground. Lubricate as needed. Give the lube enough time to penetrate, then start the engine. If the machine continues to take off by itself even after the clutch has been oiled, the clutch is burned up and must be replaced.

Erratic Engagement of Clutch

As described in gas scooter clutches and transmissions your gas scooter clutch is has several moving parts that must operate in concert with each other if your gas powered scooter is to function correctly. Several things can cause a centrifugal clutch to grab or slip unexpectedly.

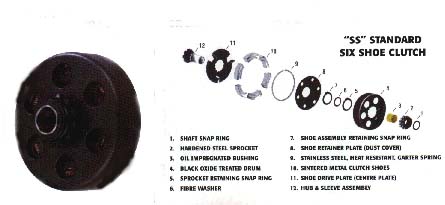

- The clutch consists of three parts:

- An outer drum that turns freely - This drum includes a sprocket that engages the chain. When the drum turns, the chain turns.

- A center shaft attached directly to the engine's crankshaft - If the engine is turning, so is the shaft.

- A pair of cylindrical clutch weights attached to the center shaft, along with a spring that keeps them retracted against the shaft

-

Oil the bushing that is located in the sprocket at least every two (2) hours of driving time. Where do you oil it? Right where you see the snap ring on the sprocket at the end of the clutch. There is a bronze bushing behind the snap ring that needs lubrication. With the engine off, squirt several drops of oil while the bushing is warm. At the same time lube the chain. Use a good motorcycle chain lube. Once the chain gets "kinky" from lack of oil it should be replaced before it does damage to the clutch sprocket. A new chain is cheaper than a new clutch. If you keep the clutch and chain lubricated you should get years out of both. Oiling the chain after it gets dried out is a waste of time. Remember it is preventive maintenance, which means before the items get ruined.

-

Don't put oil inside the clutch. The holes on the drum of the clutch are to let the hot air out of the clutch. DON'T SQUIRT OIL IN THESE HOLES!! When oil gets in the drum portion of the clutch it will cause excessive slippage, which means undue heat will be generated.

-

If your gas scooter has a grease fitting in the crankshaft for lubrication then a shot of grease twice a month should be sufficient lubrication. The grease is coming from the inside of the sprocket outward, which is a better way to lubricate the clutch. The keyway in the crankshaft acts as a reservoir for the grease, which cuts down on the frequency needed for maintenance compared to oiling the snap ring area. Dirt and sand will wear the chain as well as the sprockets so do not overdo.

-

Check to make sure that the chain is not too tight and be sure that the brakes release freely when not engaged. Check them by lifting first the front then the back tires in the air and have someone spin the tires to see if the brakes are indeed dragging. If they drag when the scooter is cold, they will heat up and grab when the gas scooter gets hot.

-

Driving too slowly: A centrifugal gas scooter clutch starts to engage around 2,000 rpm and will lock up around 2,600 rpm. It would seem just the opposite but driving at speeds that allow the clutch to fully engage gives the clutch a chance to cool down. When the clutch is allowed to fully engage at high RPM it locks the shoes in the clutch against the drum and no slippage occurs. When the clutch is not locked up, the shoes can slip against the drum which causes heat that can dry up the lubrication in the oil impregnated bronze bushing. The tremendous amount of heat generated can also anneal (soften up) the clutch shoe return spring which is the heart of the clutch. If the shoes turn a blue-purple color from excessive heat, it's more than likely the clutch is ruined and the spring no longer has the ability to pull back the shoes at idle.

-

Changing the size of the gas scooter tires. Putting on tires that are larger than what came with the scooter will result in clutch problems. Tires exceeding 13" in diameter stress out a clutch if the gas powered scooter is not properly geared for the larger tires. If you are driving on smooth flat terrain than you may be able to get by with larger tires but once you get on hilly terrain, deep grass, then you are putting additional strain on the clutch, which will cause premature wear. Generally this is not such a big issue, since gas scooter frames rarely accommodate a larger tire. But, it means that if you ever replace your gas scooter clutch, you have to make sure you get a clutch that is rated for your particular scooter and tire size.

-

Weight: A centrifugal clutch is designed to be able to move a certain amount of weight. Once the weight limit is exceeded, then the life of the clutch will be shortened. A good rule of thumb is the scooter and driver should not exceed 250 pounds. The gas scooter weighs around 50 pounds so add to this the driver . If you know ahead of time that you will exceed the 300 pounds then buy a torque converter gas scooter and avoid the problems of burning up the clutch asking it to do more than it was designed for. A torque converter has a variable speed system between the driver and the driven pulleys so it can improve the gear ratio when climbing hills, which gives the torque converter an advantage over a straight clutch system. It improves the ratio by approximately 3:1 and can turn larger tires and drive at slower speeds without doing any damage to the clutch system. A torque converter is a more expensive system initially but it will last longer and is more trouble free when maintained.

-

Speed Restrictors: Do not try and reduce a gas scooters speed by limiting the travel of the throttle or by putting a restrictor in the carburetor to limit full rpm. Either of these methods will result in the clutch slipping, which is self-destructive. A gas scooter clutch needs full rpm to lock up as quickly as possible to be able to start to cool down.

Tips to Remove an Old Clutch

- Always make sure all the pieces of the old clutch are removed from the crankshaft before attempting to install a new clutch It is not uncommon to think all of the old clutch has been removed when it hasn't.

- If your crankshaft is rusty, clean the end of the crankshaft with a wire brush. You should be able to see the end of the keyway cut into the crankshaft. Dig as much rust as you can out of the keyway and spray some penetrating oil between the clutch hub and the crankshaft. There are often one or two set screws in the clutch hub, near the engine and perpendicular to the crankshaft, which bind the hub to the shaft. Remove them if they are present. If your clutch is in pieces coming off and being difficult to remove completely, disassemble all the pieces from the clutch hub. Once all the other pieces have been removed you should be able to get a grip on the clutch hub with a gear puller and pull it off (don't forget to use penetrating oil). Be sure to put a bolt in the end of the crank to protect the threads inside. If you don't have one, you can rent a gear puller from an auto-parts store for around $10.00 to $20.00 a day.

- If a gear puller won't work you will have the cut the clutch hub off without damaging the crankshaft or oil seal. A cutting torch will most certainly burn your oil seal, so replace the oil seal if you use heat. A high-speed die-grinder with a thin abrasive disk cutting wheel is one possible tool to use in this situation. Score a deep gouge in the thick part of the clutch hub, parallel to the crankshaft, being careful not to cut all the way to the crank. Then use a blunt chisel and a hammer to break the clutch hub along the score line. This loosens the hub enough that it comes off easily with a puller.

We try to answer all your questions in the articles above. Still have a question? Write to us at info@gas-scooters-on-the-web.com and we'll answer it.

GOT GAS SCOOTER PARTS?

I get mine from Neo Scooters. What you see below are actual pictures from their parts catalog. No more guessing if you have the right part by an obscure description. They sort by the model of your scooter and have pictures of each part, with the price and part number. With Free Shipping Included, you cannot go wrong. Look for their parts link in the lower left corner of the page the link above on the Neo logo) takes you to.

Not convinced that you need another newsletter?; Had you signed up earlier you would have been the first to know about Neo Scooters huge February sale. You would have heard about Rad Scooters buy one get one for half price Dirt Dog sale. You would have been the first to see the new Bladez Moby XL monster just released by Trendtimes.com.

And better yet, you would get these articles delivered directly to you. Sign up for our newsletter and have this online gas scooters content delivered directly to your mailbox. Feel free to .

Learn About Gas Scooters

| Brakes | Footdecks |

| Drives | Shocks |

| Engines | Tires |

| FAQ | Moped |

| Mini Choppers |

Compare Gas Scooters

Gas Scooter Reviews

Mini Chopper Prices w/ reviews

Buy Gas Scooters

Maintain Gas Scooters

Troubleshoot Gas Scooters

Our Gas Scooter Site